最佳芯片验证工具

Cadence® Physical Verification System(PVS) 是由 EDA 软件商 Cadence 所提出之新一代芯片验证工具,它不仅能使用于类比 / 数字 / 混合信号之设计平台,如 Virtuoso IC Layout Platform、Encounter,且更与寄生参数萃取软件集成,如 QRC,以萃取布局后寄生参数,提供用户在芯片后段验证的完整解决方案。

随着半导体制程的发展趋势,芯片后段验证 (Back-end Verification) 所耗费的处理时间与复杂度不断提升的情况下,Cadence® Physical Verification System (PVS) 验证工具,凭其线性化的优异性能表现(Performance),不仅能减少运算处理时的等待时间;另外其创新的实时侦错 (Time-To-Error) 功能,实时侦错已运算完成部份,让使用者不再浪费时间等待运算结果,再者,其新创的人性化图形除错界面 (Graphic LVS Debug Interface ) 及交互式短路侦察系统 (Interactive Short Locator),不仅能有效弥补侦错经验不足的困扰,更能有效缩短来回除错所耗费的时间 (Turn Around Time),以提升工程师的效率及芯片产出。

此外,Cadence® Physical Verification System(PVS) 不仅同时支持 GDSII 与 Open-Access 的格式,亦兼容于目前工业界标准的验证语言,以降低工程师跨平台使用上的额外工作与难度。

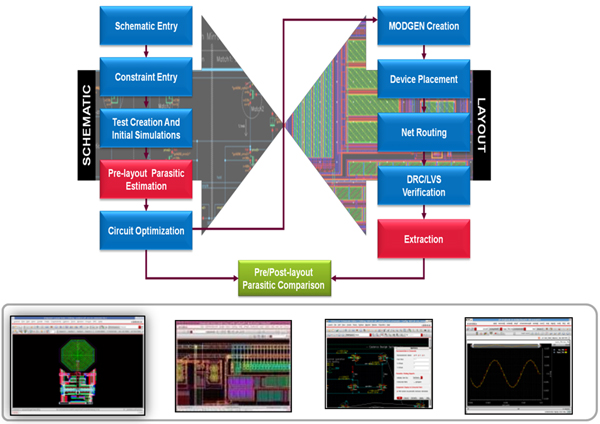

Physical Verification System (PVS) 流程图

Physical Verification System (PVS) 后段验证解决方案

Physical Verification System (PVS) 特点

成功经验

超过 50 位以上使用客户,包括晶圆厂及芯片设计公司 |

|

使用不同晶圆厂之不同制程下投片成功,包括成熟制程,如 130 / 90 / 65nm 及先进制程,如 45 / 40 / 28nm |

竞争力的性能表现

优异的单处理器 (singleCPU) 运算性能 |

|

支持单机多核心或多机多核心 |

|

线性化运算处理能力 |

有效率的分析及侦错接口

集成式侦错环境 |

|

实时侦错 (Time to Error) |

|

图形化除错接口 (Graphic LVS Debug Interface) |

|

交互式短路侦查系统 (Interactive ShortLoctor) |

跨平台集成

集成 Virtuoso customer IC layout platform 与 Cadence digital IC Encounter platform |

|

集成 Cadence QRC extraction,提升布局后寄生参数萃取之完整流程 |

晶圆厂级的设计服务

配合晶圆厂 Process Design Kits (PDK) 提供芯片设计所需文件数据 |

|

相容于台积电验证之 iDRC / iLVS design kits |

转换无障碍

相似之用户接口,熟悉度高易上手,操作无障碍 |

|

内建类似业界标准与法之 DRC / LVS 命令文檔,兼容性高 |

|

支持业界标准语法之 DRC / LVS 命令文文件 |

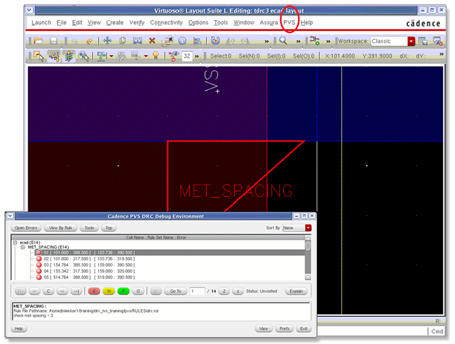

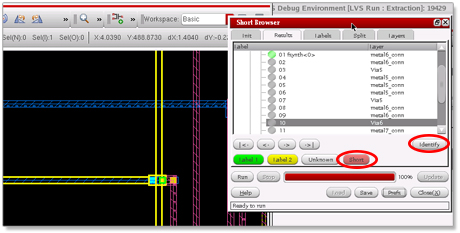

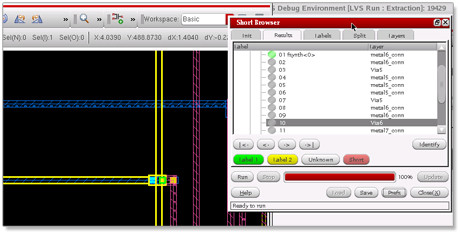

PVS DRC

Easy to use one window interface |

|

Time to error |

|

- Error Browser will pop up and allow viewing of errors while job is still running |

|

Standard DRC Browsing capabilities |

|

- By Cell/ By Rule |

|

Error Waivers |

|

- Persistent and loadable in subsequent runs |

Time To Error

Error Browser will pop up and allow viewing of errors while job is still running.

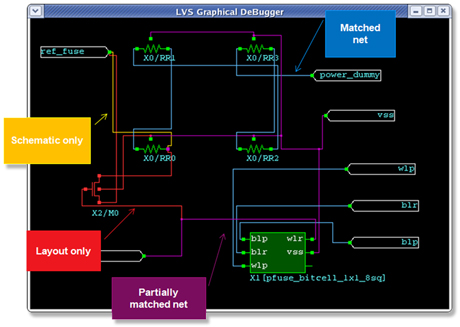

PVS LVS

Rapidly identifies complex LVS mismatches

Graphic LVS Debug accelerates identification of complex LVS mismatches in chip designs |

|

- Compares logical and physical design using a common schematic representation |

|

- Guides navigation using design errors |

|

- Can be launched with LVS debug environment, and graphical elements can be probed through the LVS debug environment |

|

- All errors and warnings are easily navigated and show surrounding context |

Strong functionalities and flexible usability

Error Tags |

|

World view or detail view |

|

Filter net, devices for better understanding of error |

|

Drill down for more information on points of interest |

|

etc |

LVS Hyper debugger - Graphical LVS Debug

LVS debug is extremely time-consuming and experience dependent

Limitation of current tools |

|

- Static error report in batch mode, contain large data, difficult to understand |

|

- Errors in text report hard to identify relationship |

|

- User cannot actively query more information on points of interest |

|

- Not allow easy navigation of the original design |

|

Bind-key - Cadence Composor like |

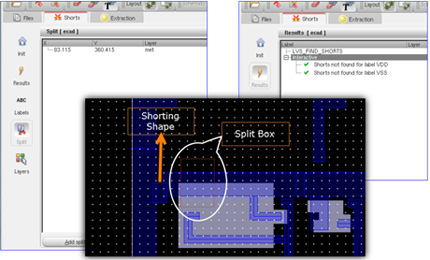

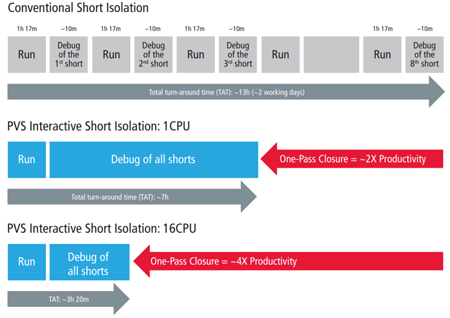

One-pass short isolation

Locating shorts found in old-fashion LVS comparison report requires |

|

- Additional manual work |

|

- Additional LVS extraction and comparison runs |

|

PVS approach facilitates one-pass short isolation for cell / block / full-chip designs |

|

- Run time typically <10% of extraction time and scales up to 5x with 8 CPUs |

|

- Start debugging while run is in progress as soon as first results are available |

Interactive Short Locator - Comparison with and without the Interactive Short Locator

PVS to QRC interface

Fully solution for back-end verification

Support Cadence QRC flow to complete post-layout simulation

No additional licenses required to enable flow |

|

Provides complete QRC GUI support |

|

TECHLIB feature makes PVS QRC flow easy to use |

|

Batch / interactive use model |

|

Support Spice, SPEF, DSPF, extracted view, etc. flows |

|

Parity of flow between PVS / Assura = easy transition |